Acoustic Revive R-AU1-PL 1.0m USB Cable

NEW Acoustic Revive R-AU1-PL 1.0m USB Cable

- USB cable: 1.0m

- Power supply / Signal complete separate.

- Adopted PC-TripleC.

- Fluororesin insulation.

- Adopted natural silk for cushioning material.

Principle and structure

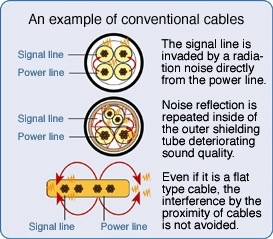

Problems of conventional USB cables

Did you know that the signal line and power supply line are installed together in parallel in all of conventional USB cables? It is widely known amongst audiophiles that the radiation noise of power cables affect signal cables and damage sound quality when a signal cable and a power cable are installed in parallel or come into contact with each other.

However, most USB cables available on the market have the signal line and power line in one cable together - we can easily imagine how sound quality is deteriorated by this structure. Furthermore, the power supply lines in USB cables transmit a large amount of ‘noise’ that is generated by the P/C (computer). This ‘noise’ seriously degrades the quality of the signal being transmitted and therefore, audio sound quality is greatly reduced.

Attempts to shield on cable from the other (inside the same cable) is not effective in avoiding influences from the power line to the signal line.

Some high-end USB cables made by audio cable manufacturers have independently shielded signal line and power lines, however, these two lines are in close proximity in the same cable and it is impossible to avoid influence from the power line to signal line.

In addition, this structure is constantly causing noise reflections inside the outer shielding tube which will significantly damage sound quality.

A world first ! Perfectly separated and independent signal line and power supply line !

USB-1.0SP TripleC-FM and USB-1.0PL TripleC-FM are equipped with two independent cables consisting of a two-core shielding structure with a 100% shielding effect obtained by using a copper foil. This is the only USB cable which is successful in stopping noise interaction between the power and signal lines.

We can obtain further improvements in sound quality by employing two A-Plugs to separate the Signal and power lines from the output terminals.

USB-1.0SP employs two A-Plugs for the output side to achieve perfect separation of the signal line and power supply line.

A P/C is normally equipped with several USB outlets conveying the same signals, therefore, you can bring out the Signal and Power lines separately from the output, resulting in a dramatic improvement in sound quality, channel separation and S/N ratio.

A very thick 0.8 solid core conductor is used, fully exploiting the limits of USB connectors

USB-1.0SP and USB-1.0PL USB cables are 100% Made in Japan and are equipped with a very thick diameter 0.8mm Solid single-core TripleC conductor (the highest diameter USB cable currently available on the market) to achieve an overwhelming D range and F range that was impossible to create by conventional USB cables.

Our maximum technology to realize the highest-end sound quality, i.e. l Conductor: Thick 0.8mm (diameter) Solid single-core TripleC (the highest diameter USB cable currently available on the market)

The purity of TripleC exceeds the high purity copper such as 6N when it is made into a cable, and its overwhelming conductivity is far superior.

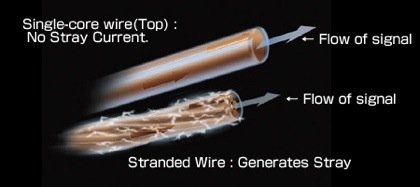

We also applied TripleC as a solid single-core to avoid stray current(Strand jump phenomenon) and to achieve an accurate digital transmission, resulting in a clear and blur-less sound image, wide and deep sound field with an accurate phase and a full three-dimensional acoustic field.

Signal transmission concept of Single-core wire and Stranded wire.

Maximum technology without compromise into the terminal and cable structure as well.

l Original USB plug made from a solid block of 2017S air craft grade aluminum alloy to improve vibration control effect.

l Outer shielding with Carbon SF tube to prevent exterior noise, radiation noise generated from the cable and the electrostatic charge of the cable itself, leading to a perfect separation of the signal line and power supply line.

l The connection between cable and USB plug is made with a high grade solder for audio use. It is not possible to use this solder for conventional molded USB cables.

Free for ordering any extra length.

As most conventional USB cables are molded cables, you are unable to order a specific length suitable for your use, however, you can order any length of USB-1,0SP and USB-1.0PL for your equipment because our USB cables are fully handmade by skilled craftsmen.

Introduction to Acoustic Revive USB Cables

We are much pleased to introduce you an epoch-making Audio USB cable from Acoustic Revive.

You would be surprised to experience so big difference of the sound comparing to conventional USB cables(for audio application).

PC-tripleC conductor, single line of superiority

- Realization air insulation structure, the Teflon insulated by ultra-high CP price

- Copper foil shield, tourmaline impregnated sheath to prevent external noise

A world first ! By using traditional Japanese forging processes, a new ‘ultimate’ conductor has been produced.

Forging process

Copper is compressed to 70% by forging tens of thousands of times by gradual application of pressure with a fixed angle and direction. (The constant angle continuation transfer forging method). By using this forging process, the transverse crystal grain boundary changes and becomes more longitudinal, crystals now have consecutive connections which makes current flow extremely smooth.

In addition, by forging, the conductor density is dramatically improved by destroying the internal air grains. This, in turn, improves the conductivity and the acoustic signature of the copper.

A conductor section before forging process

Electric current flow: The crystal structure and grain boundaries that are formed in a transverse state are a disturbance to the electric current and signal transmission.

So the Crystals and grain boundaries that were in a transverse state are elongated and become more longitudinal when they are forged repeatedly in the same direction.

By further continuous forging, crystal structures and grain boundaries are subdivided and lined up longitudinally which generates a smoother signal transmission.

Annealing process after core-wire processing

PC-TripleC wire after "Continuous Crystal Construction" process is further processed by Transfer Forging method for thinner wire.Then Annealing process is carried out under a temperature and time control depending on a thickness of the wire.In result, crystals fuse each other and change into more consecutive crystal.

Introduction to Acoustic Revive Triple-C conductors

PC-CCC(Pure Copper-Continuous Crystal Construction) was developed by Japanese craftsman works as a successor of PC-OCC which dominated in the audio industry for many years.

PC-CCC is now causing a sensation on several medias in Japan as a the savior of the audio industry:

http://www.phileweb.com/interview/article/201401/23/217.html

http://av.watch.impress.co.jp/docs/topic/20140123_629675.html

http://www.promotion-works.com/pc-triplec.html

http://www.itmedia.co.jp/lifestyle/articles/1401/22/news137.html

infact, some time after...

"As we informed you, Acoustic Revive PCOCC-A cables will be replaced by PC-TripleC conductor gradually from May onward. The attached information sheet is a copy of a panel to be used at Munich High-End Show in May".

"This is really a superior conductor that is possible to produce only by Japanese traditional forging process".

further information..

Apart from the new epch-making conductor "PC-TripleC", the new cables are equipped with a new material "FINEMET Beads" which perfectly cancels the noise on transmission:

http://www.hitachi-metals.co.jp/e/products/elec/tel/p02_25.html

http://www.hitachi-metals.co.jp/e/products/elec/tel/pdf/hl-fm4-f.pdf

By these two synergistic effects, the new cables make a wonderful improvement of the sound quality as if the audio system was changed, realizing a super high S/N ratio and a dramatic improvement in sound quality without sacrificing any sound and musical elements of the master sound source.

Leave a review