Acoustic Revive POWER Standard-tripleC-FM Power Cable

Acoustic Revive PSE* Certified Hi-End Power Cable POWER STANDARD-tripleC-FM, 2 meter length - Highest quality PSE acceptable power supply cable, terminated Schuko+IEC.

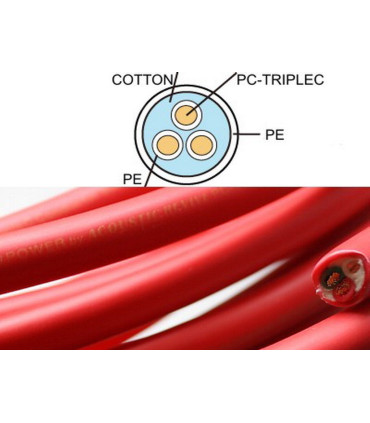

Principle and structure

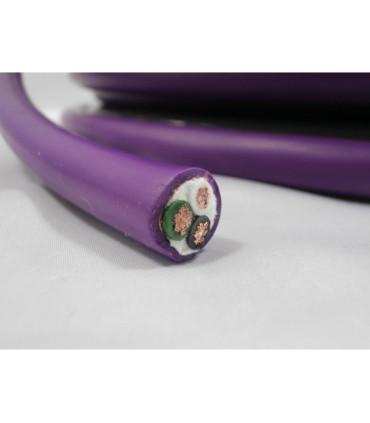

Epoch-making cable structure. Highest quality PSE acceptable power supply cable. Adopted 3.5 square, very thick structured tripleC. It has an overwhelming purity, uniformity and conductivity.

For shield, three different hardness macromolecule polyolefin is used for effective vibration control. Assortment shield tends to destroy sound by straying electric current. Instead, we adopted copper foil shield to stop outbreak of straying electric currect. For the surface, ACOUSTIC REVIVE`s carbon SF tube (CSF) is used to protect from radiation noise and noise from outside.

Sound of POWER STANDARD

POWER STANDARD is probably the most natural sounding and price-quality ratio power supply cable on the market. Excellent S/N ratio, very wide frequency and dynamic range. Also it`s flat balanced, sound position and 3D sound image is breath taking! It will upgrade your equipment without adding any unnecessary sound. It will bring out the full potential of your equipment!

A world first ! By using traditional Japanese forging processes, a new ‘ultimate’ conductor has been produced.

Forging process

Copper is compressed to 70% by forging tens of thousands of times by gradual application of pressure with a fixed angle and direction. (The constant angle continuation transfer forging method). By using this forging process, the transverse crystal grain boundary changes and becomes more longitudinal, crystals now have consecutive connections which makes current flow extremely smooth.

In addition, by forging, the conductor density is dramatically improved by destroying the internal air grains. This, in turn, improves the conductivity and the acoustic signature of the copper.

A conductor section before forging process

Electric current flow: The crystal structure and grain boundaries that are formed in a transverse state are a disturbance to the electric current and signal transmission.

So the Crystals and grain boundaries that were in a transverse state are elongated and become more longitudinal when they are forged repeatedly in the same direction.

By further continuous forging, crystal structures and grain boundaries are subdivided and lined up longitudinally which generates a smoother signal transmission.

Annealing process after core-wire processing

PC-TripleC wire after "Continuous Crystal Construction" process is further processed by Transfer Forging method for thinner wire.Then Annealing process is carried out under a temperature and time control depending on a thickness of the wire.In result, crystals fuse each other and change into more consecutive crystal.